Wire harness processing technology

With the rapid development of electronic technology such as electronic equipment and automobiles, the market demand for wire harness continues to grow. At the same time, it also puts forward higher requirements for functions and quality such as miniaturization and lightweight.

Next, shungal Shunjia brand harness supplier will introduce the necessary appearance inspection items to ensure the harness quality. It also introduces the application case of using a new 4K digital microscope system to realize amplification observation, measurement, detection, evalsuation and quantification and improve operation efficiency.

Harness with increasing importance and requirements

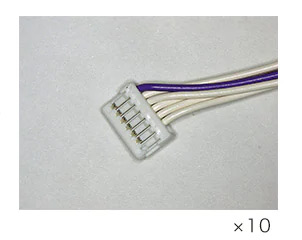

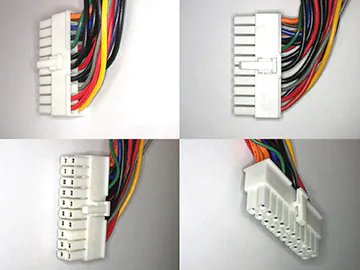

Wire harness, also known as cable harness, is a component formed by bundling the multi-channel electrical connection (power supply, signal communication) wiring required to connect electronic equipment into a bundle. By using the connector integrating multiple contacts, the connection can be simplified and misconnection can be prevented at the same time. Take the automobiles as an example, 500 to 1500 wire harnesses will be used in one automobiles, which can play the same role as human blood vessels and nerves. The poor and damaged harness will have a great impact on the quality, performance and safety of the product.

In recent years, motor products and electronic equipment have shown the development trend of miniaturization and high density. In the automotive field, ev (electric vehicle), HEV (hybrid electric vehicle), driving assistance function based on induction technology and automatic driving are also developing rapidly. In this context, the market demand for wire harness continues to grow. In terms of product research, development and manufacturing, it has also entered a new era of pursuing multi variety, miniaturization, lightweight, high functionality and high durability, striving to meet various needs. In order to meet these needs and quickly provide high-quality new and improved products, the evalsuation during research and development and the appearance inspection in the manufacturing process must meet the requirements of higher correctness and speed.

The key to quality is the terminal connection and appearance inspection of wires

In the manufacturing process of wire harness, an important process to determine the quality of wire harness, that is, the terminal connection of wire, needs to be carried out before assembling connectors, wire tubes, protective tools, wire clamps, tightening clamps and other components. When connecting terminals, the processes of "crimping (caulking)", "pressure welding" and "welding" will be adopted. When using various connection methods, once the connection is abnormal, it may lead to poor conductivity, core wire falling off and other faults.

There are many methods to detect harness quality, such as using "harness tester (continuity tester)" to check whether there are electrical disconnection, short circuit and other problems.

However, in order to detect the specific state and causes after various tests and when faults occur, the appearance inspection and evalsuation of the terminal connection part must be carried out with the help of the magnification observation function of the microscope and microsystem. The appearance inspection items of various connection methods are as follows.

Visual inspection items of crimping (caulking)

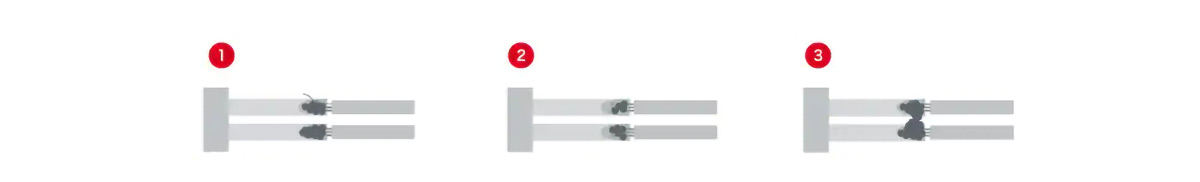

Crimp the cable and sheath through the plasticity of copper clad conductors of various terminals. Use tools or automatic equipment on the production line to bend and connect the copper clad conductor through "caulking".

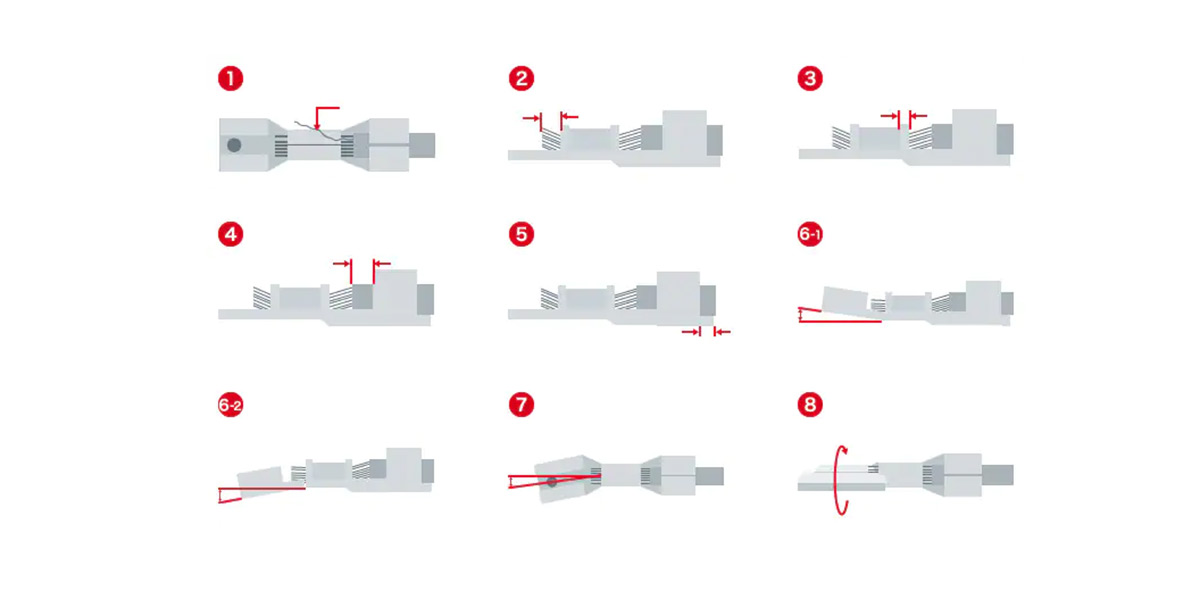

【Appearance inspection items】

| (1)Core wire protrusion | (2)Core protruding length | (3)Bell mouth volume | (4)Sheath protrusion length |

| (5)Cut length | (6)-1 bend up / (6) - 2 bend down | (7)Rotate | (8)Wobble |

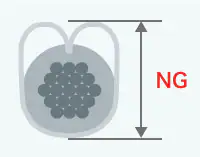

Criterion for judging crimping quality of crimping terminal "crimping height"

After the terminal crimping (caulking) is completed, the copper clad section height of the conductor at the caulking of the cable and sheath is the "crimping height". If the caulking is not carried out according to the specified crimping height, it may lead to poor conductivity or cable falling off.

OK / ng example of crimping height of sheath part

|  |  |

Good product (within specified tolerance) | Insufficient crimping | Excessive crimping |

If the crimping height is higher than the specified value, it will lead to "insufficient crimping" and the wire will loose under the action of tension. If it is lower than the specified value, it will lead to "excessive crimping", and the copper clad conductor will pull into the core wire, resulting in damage to the core wire.

The crimping height is only the judgment basis for inferring the state of sheath and core wire. In recent years, under the background of miniaturization of wire harness and diversification of materials used, in order to comprehensively detect all kinds of defects in caulking process, quantitative detection of core wire state for crimping terminal section has become an important technology.

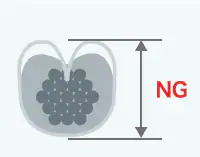

Visual inspection items of pressure welding

Insert the sheathed wire into the seam to connect it to the terminal. When the wire is inserted, the sheath will contact with the blade installed at the seam and be pierced to produce conductivity, eliminating the step of stripping the sheath.

[appearance inspection items]

(1) Super long wire

(2) gap at the top of the wire

(3) conductor protrusion before and after the pressure welding sheet

(4) offset of the pressure welding center

(5) defects of the outer cover

(6) defects and deformation of the pressure welding sheet

A: Cover B: pressure welding piece C: wire

Visual inspection items of welding

Representative terminal shapes and cable arrangement methods can be divided into "tin slot type" and "round hole type". The former passes the wire through the terminal and the latter passes the cable through the hole.

[appearance inspection items]

(1) Core wire protruding (2) poor conductivity of solder (insufficient heating) (3) solder bridging (excessive welding)

Application case of harness appearance inspection and evalsuation

With the miniaturization of wire harness, it is more and more difficult to detect and evalsuate the appearance based on enlarged observation.

Keenshi's ultra-high precision 4K digital microscope system not only realizes high-level magnification observation, appearance inspection and evalsuation, but also greatly improves the operation efficiency.

Depth synthesis of full range focusing on three-dimensional objects

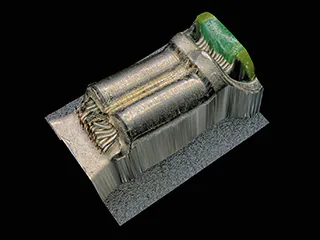

The harness is a three-dimensional object, which can only focus locally, so it is difficult to carry out comprehensive observation and evalsuation covering the whole object.

The 4K digital microscope system "VHX series" can use the "navigation real-time synthesis" function to automatically carry out in-depth synthesis, shoot ultra-high fine 4K images focusing on the whole target, and easily carry out correct and efficient magnification observation, appearance detection and evalsuation.

Enlarged image of core wire caulking taken by 4K digital microscope system "VHX series"

|  |

Full focus image without depth synthesis (100 ×) | Full focus image after depth synthesis (100 ×) |

Warpage measurement of harness

When measuring, we must not only use a microscope, but also use a variety of other measuring instruments. The measuring process is cumbersome, time-consuming and laborious. In addition, the measured values cannot be directly recorded as data, and there are some problems in operation efficiency and reliability.

4K digital microscope system "VHX series" is equipped with diversified tools of "two-dimensional dimension measurement", which can complete the measurement with simple operation when measuring various data such as harness angle, crimping terminal section and crimping height. The use of "VHX series" can not only realize quantitative measurement, but also save and manage images, values, shooting conditions and other data, so as to improve the operation efficiency by leaps and bounds. After the data saving operation is completed, you can still select the past images from the album and carry out the measurement of different positions and items.

Measure the warpage angle of harness with 4K digital microscope system "VHX series"

Using the diversified tools of "two-dimensional dimension measurement", quantitative measurement can be easily completed by clicking the correct angle.

Observation of core wire caulking not affected by metal surface gloss

Under the influence of the reflection of the metal surface, it sometimes occurs to observe.

The 4K digital microscope system "VHX series" is equipped with the functions of "eliminating halo" and "removing annular halo", which can eliminate the reflection interference caused by the luster of the metal surface and correctly observe and master the caulking state of the core wire.

Observe core wire caulking with 4K digital microscope system "VHX series"

|  |

Without removing halo and ring halo( × 20) | Eliminate halo and ring halo( × 20) |

Zoom shooting of wire harness caulking part

Have you ever experienced that it is difficult to focus accurately on small three-dimensional objects such as wire harness caulking during appearance inspection, which makes it very difficult to observe small parts and fine scratches.

4K digital microscope system "VHX series" is equipped with electric lens converter and high-resolution HR lens, which can carry out automatic magnification conversion of 20 to 6000 times to achieve "seamless scaling". Simply operate the mouse or controller at hand, and you can quickly complete the magnification observation.

Zoom image of crimping terminal taken by 4K digital microscope system "VHX series"

|  |  |  |

Omnidirectional observation system for realizing high efficiency of three-dimensional object observation

When observing the appearance of three-dimensional products such as wire harness, the operation of changing the angle of the target and then fixing must be repeated, and each angle must be focused separately. Not only can it focus locally, it is also difficult to fix, and there is an angle that cannot be observed.

4K digital microscope system "VHX series" can use "omni-directional observation system" and "high-precision x, y and Z electric stage" to support the flexible action of sensor head and stage that can not be realized by some microscopes.

With the adjustment device that can easily adjust the three axes (field of view, rotation axis and tilt axis), it can be observed from all angles. Moreover, even if it is tilted or rotated, it will not jump out of the field of view and keep the target in the central position, which greatly improves the efficiency of three-dimensional object appearance observation.

Tilt observation of connector part with 4K digital microscope system "VHX series"

|  |

| Omnidirectional observation system "and" high precision x, y, Z electric stage " | Tilt observation of connector (5 ×) |

3D shape analysis for quantitative evalsuation of crimped terminals

When observing the appearance of the crimping terminal, it is not only necessary to focus the three-dimensional object in different areas, but also there are some problems, such as missing abnormality, artificial evalsuation deviation and so on. For three-dimensional objects, they can only be evalsuated by two-dimensional dimension measurement.

4K digital microscope system "VHX series" can not only enlarge and observe and measure two-dimensional dimensions with clear 4K images, but also shoot 3D shapes, measure three-dimensional dimensions and measure the contour of each section. Without the skilled operation of the user, it can also complete the analysis and measurement of 3D shape through simple operation, and can realize the high and quantitative evalsuation of crimping terminal appearance and the high efficiency of operation at the same time.

Analysis of 3D shape of crimping terminal with 4K digital microscope system "VHX series"

|  |  |  |  |

Mosaic image (50×) | Enlarge image | 3D mosaic image | 3D enlarged image | 3D profile measurement example |

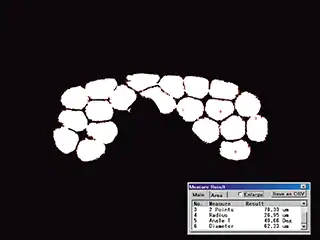

Automatic measurement of cross section of caulking cable

4K digital microscope system "VHX series" can easily complete all kinds of automatic measurement with photographed cross-section images by using rich measurement tools.

For example, as shown in the figure below, automatic measurement can be carried out only for the area of the core part of the core caulking section. With these functions, rapid quantitative detection can also be carried out for the core wire state of the caulking part that cannot be mastered only by crimping height measurement and section observation.

Automatic measurement of cross section area of core wire caulking with 4K digital microscope system "VHX series"

|  |

Image capture (100×) | Automatic area measurement for core section (100×) |

New tools for rapid response to market demand

In the future, the market demand for wire harness will be greater and greater. In order to meet the increasing market requirements, shungal brand wire harness must establish new research and development, quality improvement mode and manufacturing process based on fast and accurate detection data.

Article recommendation

-

Basis for selecting harness type

Conductor type is also called conductor type. The first step of conductor selection is to determine the category of conductor. This paper mainly introduces the category of vehicle conductor and the ba

-

Introduction to harness processing

Incoming inspection, warehousing, off-line, crimping, sub assembly, assembly, inspection (appearance / size / electrical inspection, etc.) and packaging.

-

Harness intelligent digital intelligent manufacturing capability

Although some benchmark enterprises of wire harness have made great progress in intelligence and automation in recent years, the processing of wire harness is still a labor-intensive industry.

-

China's top ten automobiles harness factories

How much do you know about China's wire harness factories after many years of experience in the automobiles connector and wire harness industry?

-

Copper prices hit a new high, making it difficult for cable manufacturers

At this stage, connector and cable manufacturers are consuming the original inventory while facing the high copper price. For this reason, they can only run in with upstream manufacturers and feed bac

-

The special cable industry has entered a period of rapid development

Special cable is a special wire and cable used in special environment or special purpose. It has some special properties through special material selection and structural design.

SHUNGAL TECHNOLOGY CO.,LTD.

Production address

121 Min'an Road, Daning, Humen Town, Dongguan, Guangdong, China.

Telephones

+86 769-8225 8081

Sales call

Nancy Peng

+86 150 0769 0603

QQ:238 556 1688

New Arrivals

Skype

Skype QQ

QQ